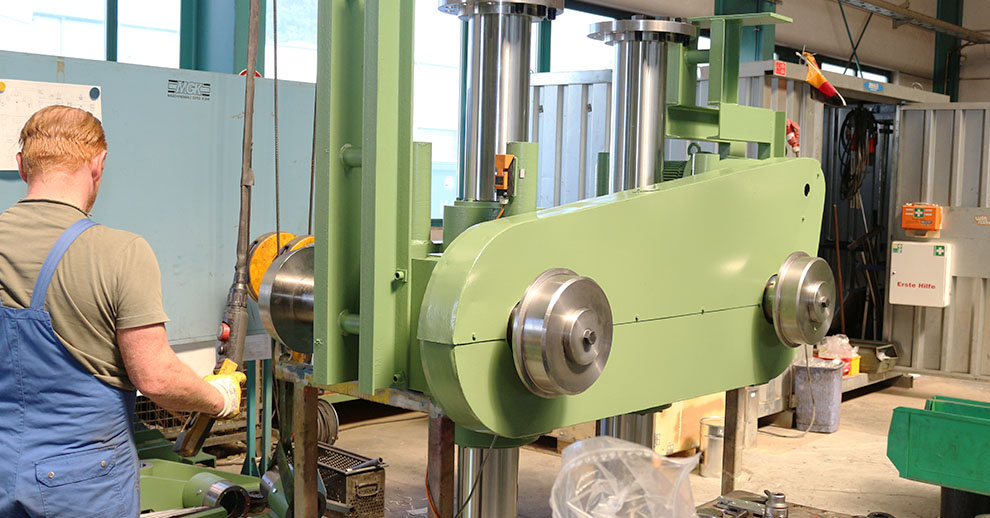

We are pleased to come by on short notice to repair failed machines. A failed machine in a conveyor system generally leads to the standstill of the entire production line.

High costs are the consequence since the staff has to be paid further even if the machines are defect. Thus, it is better to conclude a maintenance contract. Thereby we can process a special planning reliability that leads to a best possible process safety. We are aware as to when individual components reach their limit with regard to tear and wear under certain conditions.

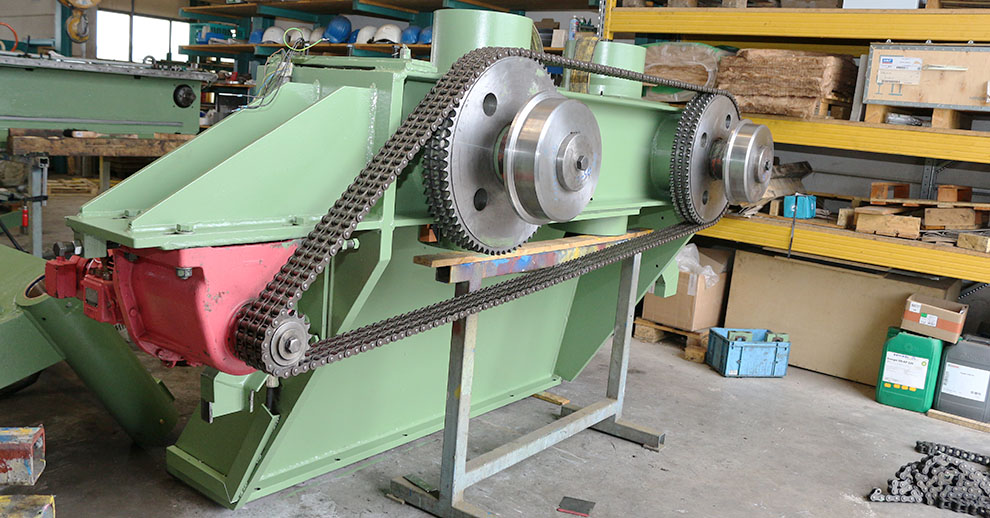

Coil inflows have highly loaded bearings, cross and cut-to-lengths lines have weaknesses at the cutters due to constructive properties and the hydraulic of coil turners are prone to a special high load, too.

We could already be on site before a failing component can cause a standstill to the production line. The means therefore are maintenance contracts. Maintenance contracts a planning reliability for our clients and us. Maintenance contracts provide us with the possibility to know always the latest condition of the system at the client’s site. With us, the client gets a highly competent producer of Special Machines as a partner who does everything to intervene always precautionary since nothing is more expensive than a standstill of a production line. With maintenance contracts, downtimes are reduced or fully eliminated by an intelligent planning. We have always an extensive spare parts inventory of our own products available, as well. As a producer of Special Machines, we can produce spare parts for third party machines, too.