Our coil wrapping systems guarantee a save, inexpensive and environmentally friendly wrapping of coils. In our production facilities, all conventional materials are save and reliably to be tailored for dispatch. Trouble-free procedure, low energy and material costs and safe operation are our priorities in the development of our coil wrapping systems. Whether aluminium, copper, brass, bronze, steel, stainless steel or other materials – our coil wrapping systems are configurable for all requirements. During our consultation and installation, we emphasize especially on the exact requirements of our clients. Therefore, an intensive discussion with the client takes place before delivery and installation of a system. We deliver and install only what the client needs. A total configuration allows us the tailoring of the coil wrapping systems as desired by the client. We do offer three different solutions as handling systems:

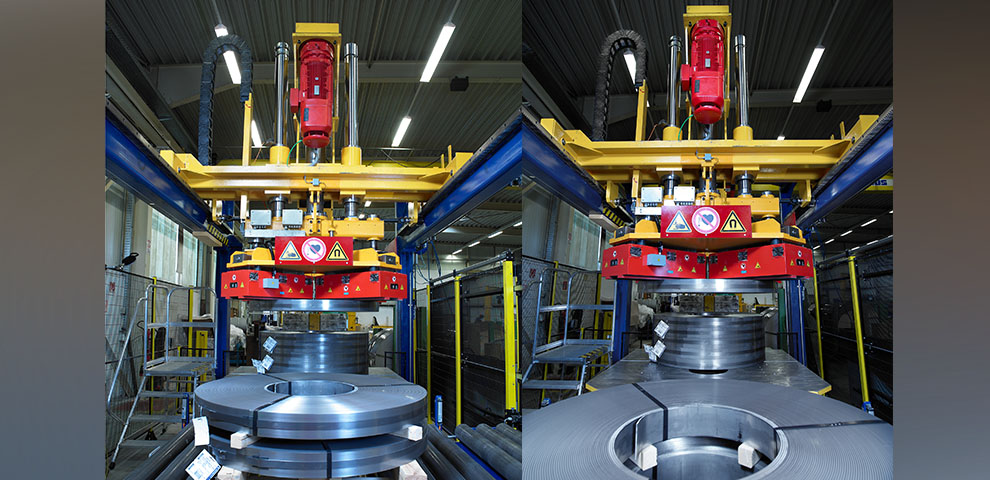

Vacuum technology for sensitive materials like aluminium sheets: aluminium or copper sheets are often used for optical veneering like roof coverings or façade engineering.

That these soft materials do not get scratched unnecessarily, our vacuum lifters lift the coils especially gentle and careful. Further lifting solutions are a combination of inner spreader and suction plate for non-magnetic metals like stainless steel sheets and lifter with permanent magnet for magnetic materials.

With further options a weigh cell and labeling, palettising including wrapping of the paletts and and integrated coil bearing the configuration of our wrapping systems are complete. We offer this equipment manually, semi-manually or fully automatic.